Graphics technology from Ilmenau

Graphics technology with precision

EST Andrä Grafittechnik GmbH

The material graphite fascinates. And just as Stefan Andrä’s great-grandfather used this material for the production of uniform glasses at the beginning of the last century, EST Andrä Grafittechnik GmbH today uses the outstanding properties of graphite for the production of various molds, dies and other products.

The versatility of this material is far from exhausted. For EST Andrä Grafittechnik GmbH, one thing is certain: graphite is the innovative material for future groundbreaking projects and productions.

Grafit - precision and variety

The material graphite impresses with its unique properties, with which it is used and processed in a variety of ways.

The reason for this uniqueness lies in its layered crystal structure. In the form of a pencil lead, he is well known. But the material is also found as a high-quality graphite fiber in tennis rackets or in temperature-resistant furnace linings. Graphite is a universal construction and support material, a good electrical conductor and in fiber form it is an unsurpassed thermal insulator.

In other words, graphite is an ingenious material.

OUR VARIETY OF SERVICES

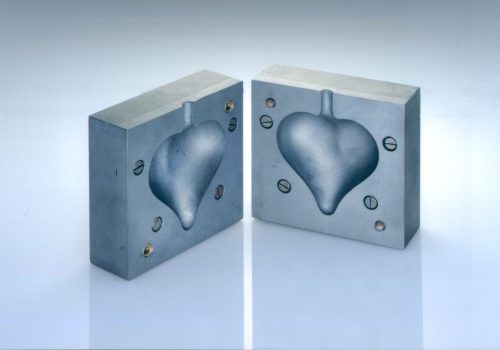

- Molds and mold rolls for glass and quartz glass technology

- Ingot molds and crucibles for metallurgy

- Boats, targets, carriers, matrices and susceptors for semiconductor technology

- Heater and liner for fiber production

- Insulations from graphite felt for furnace construction and glass and silicon smelting

- Radiation shields , Nozzle, Ion catcher for high temperature applications

- Graphite electrodes for melting processes

- Graphite turntable pads for the analog sound experience

Our demand for quality

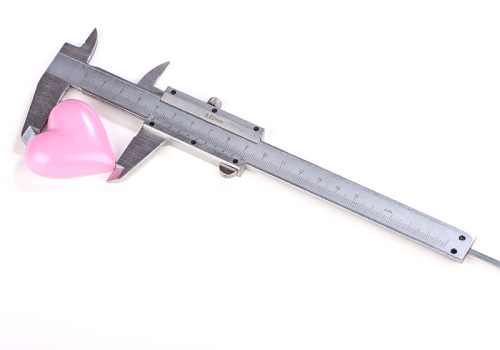

We have a clearly formulated demand for quality and this permeates our entire production. We manufacture a wide variety of workpieces, semi-finished products and parts according to your specifications and drawings.

We cooperate with renowned manufacturers and thus have a wide range of graphite types to choose from. In production, we can realize (almost) any customer request by sawing, drilling, milling, turning and grinding: from a tiny plate to a turned part of 500 millimeters in diameter or up to 2 meters in length.

In the traditional mold shop, we produce molds for a wide variety of glassware. In this process, the shape of the glass is determined with mold rolls, half molds or hinged molds. We discuss with the glassblower which variant is most suitable.

Our company has been engaged in graphite processing since 1928. This experience flows into our production as well as into our consulting. Our goal is always to find and implement a solution for our customers. In doing so, we are open to unusual approaches that often offer amazing and convincing solutions. The experience and our knowledge are the basis for our consulting. Which material is suitable? Which shape is suitable for which material? We focus on solutions, not problems.

Contact us. We will be happy to advise you!

Our products from graphite

-

Ground joint plug

20,85 € – 38,00 €excl. VAT

plus Shipping costs

Select options -

6-Kant Normschliffkohle

20,60 € – 125,00 €excl. VAT

plus Shipping costs

Select options